The company ARCOZ AG (formerly ABS-Ruefer AG) has been a specialist for automated solutions in special machine construction for small and very small parts for more than 35 years.

We have helped shape the development of digital automation with programmable logic controllers (PLCs) and the integration of PC-based control technology as well as advanced and intuitive user interface HMI. As the variety of functions and tasks grew, so did the need for individual components and modules to communicate with each other.

A further increase in performance, towards knowledge-based systems, requires new components, e.g. for knowledge acquisition and knowledge utilization. The focus here is on the interaction of the system components involved. This is what lies behind the idea of Industry 4.0.

In recent years, technological developments have also made automation economical for production with small batch sizes and short product cycles.

We offer solutions for your specific automation field from solution finding to commissioning and maintenance.

For more than 35 years, ARCOZ AG has been a specialist for automated solutions in special machine construction for small and very small parts.

We have helped shape the development of digital automation with programmable logic controllers (PLCs) and the integration of PC-based control technology as well as advanced and intuitive user interface HMI. As the variety of functions and tasks grew, so did the need for individual components and modules to communicate with each other.

A further increase in performance, towards knowledge-based systems, requires new components, e.g. for knowledge acquisition and knowledge utilization. The focus here is on the interaction of the system components involved. This is what lies behind the idea of Industry 4.0.

In recent years, technological developments have also made automation economical for production with small batch sizes and short product cycles.

We offer solutions for your specific automation field from solution finding to commissioning and maintenance.

The necessary and sensible degree of automation in the feeding, sorting and handling of small and very small parts depends strongly on the respective application and the concrete requirements.

It can therefore make perfect sense to use the respective strengths of humans and machines for some processes. Even Industry 4.0 will not want to do without human cognitive abilities entirely. In such cases, the focus is on sensible cooperation and an efficient safety concept in the design of the plant.

In other cases, complete automation may make sense. Then the requirements for throughput, precision and reliability determine whether axis systems or robots are used, for example.

Accordingly, at ARCOZ AG we offer turnkey solutions ranging from simple manual workstations to fully automated assembly and production lines, entirely according to your specific needs, and we will be happy to advise you.

You expect efficient assembly, production and testing solutions for your products. We build machines and systems tailored to your requirements and integrate corresponding processes and modules:

Feeding solution at the heart of highly reliable automation solution is a target condition. Precision, speed and reliability are crucial for a perfect automation solution, especially when handling small and very small parts.

High-resolution vision systems detect even the smallest parts through intelligent image processing. Depending on requirements, robotic pick-and-place systems with up to six axes ensure rapid, flexible and reliable placement and further processing.

By using modern and proven software solutions, we achieve a high degree of user-friendliness.

As integrators of feeding, loading and unloading, processing and inspection solutions, we ensure smooth operation across all process stages and turn hardware and software interfaces into reliable connection points.

In the fields of robotics and vision, we have been experiencing great advances for several years, not only in performance and versatility, but also in compactness and availability. To better meet the needs of our customers, we combine our traditional know-how with new technologies.

We integrate, depending on the expediency:

We work together with you, renowned institutes and suppliers to keep abreast of current developments on both the user and supplier sides.

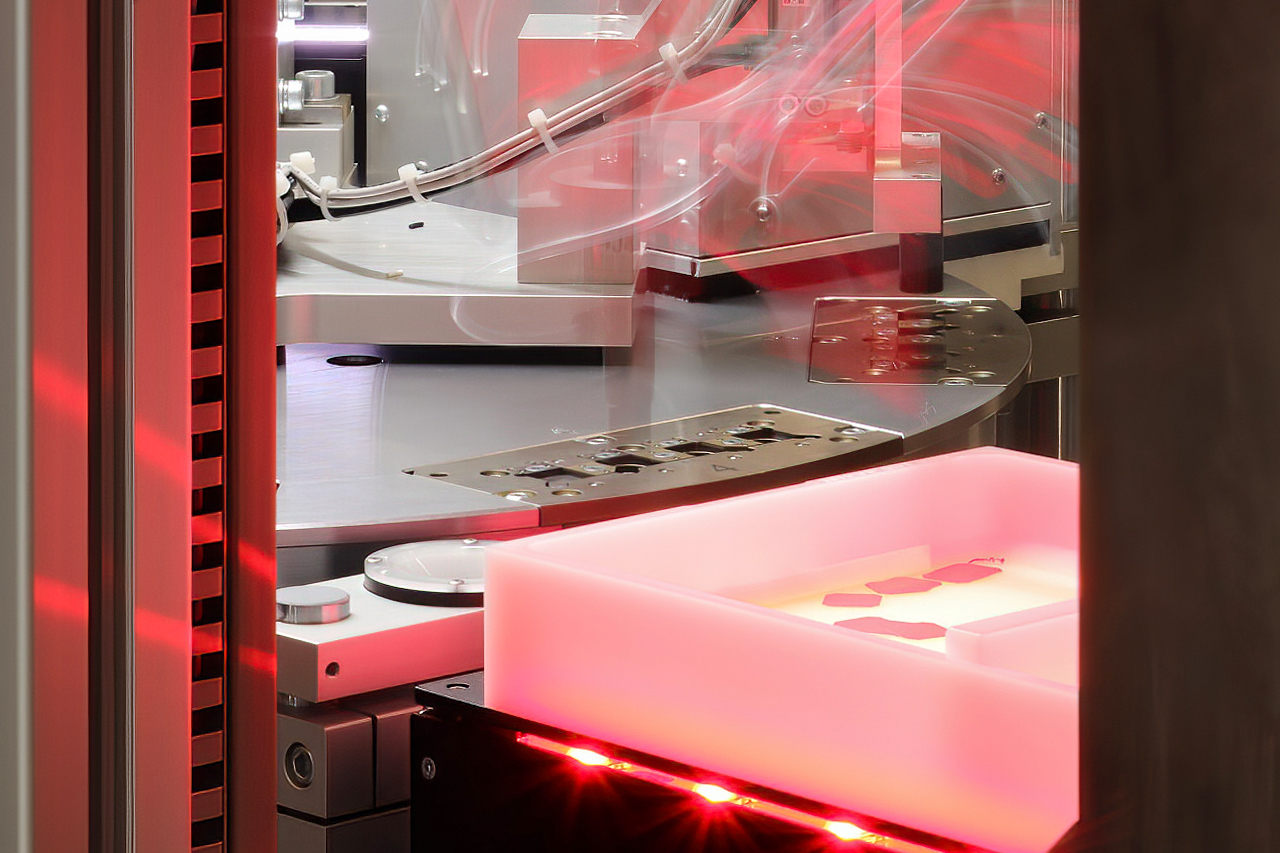

In industry, lasers are used for a wide variety of manufacturing processes - from forming, cutting, joining and coating to changing material properties. Laser technology enables very fast, precise and highly flexible automated production processes for diverse applications such as stripping, welding, marking, deburring, drilling, cutting and separating.

At ABS-Ruefer AG, laser technology has become not only an exciting technical topic but a reality. With our interdisciplinary competencies and highly specialized partner companies, we integrate safety-compliant laser sources into our fully automated special machines.

Further visions for the future of your laser applications can be developed and realized together with us!

The company ARCOZ AG offers products and complete solutions made to measure around the special machine construction.